Introduction

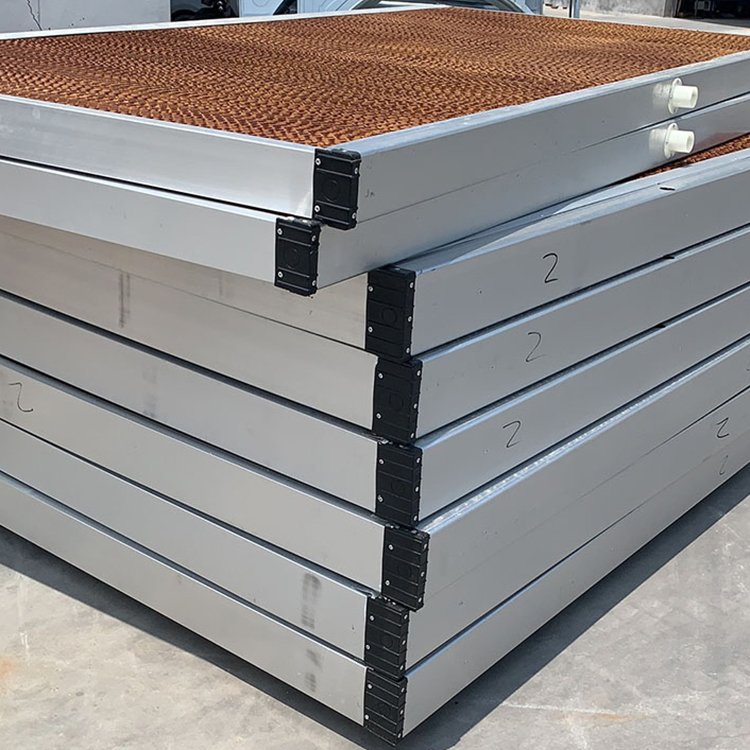

Honeycomb paper wet curtains have revolutionized cooling systems in a multitude of applications, from greenhouses to industrial cooling. Their ability to efficiently cool and humidify the air, all while being cost-effective and environmentally friendly, has made them a staple in various industries. However, to truly understand these remarkable products, it is essential to delve into the materials and manufacturing processes employed by honeycomb paper wet curtain suppliers. In this article, we will explore the common materials used, the manufacturing process, and how these factors affect the product’s performance and durability.

Common Materials Used

- Honeycomb Paper as the Core Material

At the heart of every honeycomb paper wet curtain is, quite literally, honeycomb paper. This remarkable material, made by gluing kraft paper together in a specific pattern, plays a central role in the cooling and moisture-absorption properties of these curtains. Honeycomb paper is chosen for its remarkable ability to create a labyrinth of air channels, which facilitate the passage of air and water.

One of the significant benefits of honeycomb paper is its water-absorption capacity. This material can hold a considerable amount of water, which is then gradually released into the passing air. The result is a cooling effect, particularly effective in warm and dry environments.

- Covering Materials

While honeycomb paper forms the core, covering materials wrap around it to protect and enhance its performance. The choice of covering materials is crucial, and different honeycomb paper wet curtain suppliers may use materials like kraft paper, cellulose, or other options.

Kraft paper, known for its strength and durability, is often chosen as a covering material. It provides protection to the delicate honeycomb structure and ensures the wet curtain retains its shape and functionality.

Cellulose, on the other hand, is selected for its water-absorption qualities. It helps to evenly distribute water throughout the honeycomb paper, maximizing cooling efficiency.

The choice of covering materials directly impacts the product’s strength and longevity. Different materials offer various advantages, and honeycomb paper wet curtain suppliers often make selections based on the specific requirements of the application.

The Manufacturing Process

- Material Preparation

The manufacturing of honeycomb paper wet curtains begins with the preparation of materials. The honeycomb paper is cut and shaped into the desired dimensions, while the covering materials are also prepared. The proper sizing and shaping of materials are essential for achieving the desired product specifications.

- Gluing and Bonding

A critical step in the manufacturing process involves gluing and bonding. Adhesives are carefully selected, and specific application methods are employed to ensure a secure and long-lasting bond. The honeycomb paper and covering materials are joined together to form a cohesive unit.

- Curing and Drying

Controlled curing and drying are essential for maintaining the product’s integrity. These processes ensure that the honeycomb paper and covering materials retain their desired shape and strength. The precise control of humidity and temperature is crucial during this phase of production.

- Assembly and Finishing

The final phase of manufacturing involves assembling the different components and adding finishing touches. This includes sealing the edges, combining layers, and ensuring that the product is prepared for the market. The attention to detail in assembly and finishing is a testament to the commitment of honeycomb paper wet curtain suppliers to deliver high-quality products.

Factors Affecting Product Performance

- Material Quality

The quality of materials used in the production of honeycomb paper wet curtains is paramount. High-quality honeycomb paper and covering materials directly impact the product’s cooling efficiency and moisture absorption capabilities. Using subpar materials can result in reduced product performance and a shorter lifespan.

- Bonding Strength

The adhesive quality and the strength of bonding significantly affect the product’s durability. Weak or poorly bonded layers can lead to delamination and reduced performance. Honeycomb paper wet curtains rely on a strong and lasting bond to maintain their effectiveness over time.

- Shape and Design

Manufacturing processes directly influence the shape and design of honeycomb paper wet curtains. The structure of the honeycomb paper, along with the shape and configuration of the curtain, plays a vital role in cooling efficiency and water distribution. Honeycomb paper wet curtain suppliers employ precision manufacturing techniques to ensure that the products meet specific design criteria.

- Environmental Considerations

Sustainability and eco-friendliness are increasingly important considerations in the production of honeycomb paper wet curtains. Honeycomb paper wet curtain suppliers are under pressure to use materials and processes that have a minimal impact on the environment. Many honeycomb paper wet curtain suppliers make efforts to comply with industry standards and regulations related to environmental sustainability, ensuring that their products are both effective and responsible.

Durability and Longevity

The careful selection of materials and precision manufacturing processes significantly impact the durability and longevity of honeycomb paper wet curtains. High-quality materials and strong bonds result in a longer product lifespan. However, durability also depends on other factors, such as maintenance and care.

Regular maintenance, including cleaning and ensuring proper water distribution, can help extend the product’s durability. Proper care is essential for preventing blockages and maintaining cooling efficiency. Honeycomb paper wet curtain suppliers may provide guidelines for maintenance, ensuring that the product continues to perform optimally.

The relationship between product quality and durability is crucial, especially in applications where longevity is critical. A high-quality honeycomb paper wet curtain can offer a substantial return on investment by providing effective cooling and humidification for an extended period.

Conclusion

Understanding the materials and manufacturing processes behind honeycomb paper wet curtains sheds light on the complexity and precision required in their production. These products, relied upon in various applications for efficient cooling and humidity control, owe their performance and durability to the thoughtful selection of materials and meticulous manufacturing. By prioritizing material quality and employing rigorous manufacturing standards, honeycomb paper wet curtain suppliers ensure that honeycomb paper wet curtains continue to play a crucial role in keeping environments cool and comfortable while being environmentally responsible.

Related Products