The utilization of evaporative cooling techniques in greenhouse agriculture has revolutionized the way crops are cultivated, offering an effective means to regulate temperatures and create optimal growing conditions. However, not all crops or plants respond equally to this cooling method. Understanding the suitability of different species for cultivation using evaporative cooling is crucial for maximizing productivity in greenhouse environments.

Understanding Evaporative Cooling in Greenhouses

Evaporative cooling involves the utilization of water’s evaporative properties to lower temperatures within a greenhouse. This technique relies on the principle that as water evaporates, it absorbs heat, thereby reducing the surrounding air temperature. Evaporative cooling systems typically employ pads or porous materials that are kept wet to allow for continuous evaporation, effectively cooling the air passing through them.

Factors Influencing Crop Suitability for Evaporative Cooling

- Heat Tolerance and Sensitivity: Crops vary in their sensitivity to high temperatures. Heat-sensitive plants, such as lettuce, spinach, and certain herbs, benefit significantly from evaporative cooling systems as they thrive in cooler environments.

- Water Requirements: Some crops have higher water demands or are more sensitive to moisture levels. Plants that require ample moisture, such as tomatoes, peppers, and cucumbers, can benefit from the increased humidity provided by evaporative cooling.

- Adaptability to Humidity Fluctuations: Different plant species have varying levels of tolerance to fluctuating humidity. Understanding a plant’s ability to thrive under changing humidity levels is essential when considering evaporative cooling methods.

Crops Suited for Evaporative Cooling in Greenhouses

- Heat-Sensitive Crops: Leafy greens like lettuce, arugula, and spinach, known for their vulnerability to heat stress, thrive in cooler environments provided by evaporative cooling systems. These crops exhibit improved growth and quality under regulated temperatures.

- High-Water-Demand Crops: Tomatoes, cucumbers, and bell peppers, which require consistent moisture levels, find conducive growing conditions in greenhouses equipped with evaporative cooling. Proper humidity levels aid in their development and fruit production.

- Humidity-Adaptive Plants: Some plant species, such as certain herbs (like basil and mint) and flowering plants (like geraniums or petunias), adapt well to fluctuations in humidity levels. Evaporative cooling helps maintain the moisture balance necessary for their growth.

Environmental Considerations and Crop Selection

- Climatic Conditions: Evaporative cooling is particularly effective in regions with dry or hot climates. Greenhouses in arid or semi-arid areas benefit greatly from this cooling technique, providing relief to plants during scorching temperatures.

- Geographical Suitability: Greenhouses in diverse geographical locations can leverage evaporative cooling techniques. Adaptations to microclimates within greenhouses can be made to accommodate specific crop needs based on regional variations.

Advantages and Limitations for Specific Crops

- Advantages: Evaporative cooling systems facilitate better growth, yield, and quality for suitable crops. Enhanced photosynthesis, reduced heat stress, and controlled transpiration rates contribute to overall improved plant health.

- Limitations: Certain crops, especially those prone to fungal diseases or requiring specific humidity ranges, may not thrive optimally under evaporative cooling systems. Additionally, managing humidity levels can be challenging in some environments.

Implementation and Practical Considerations

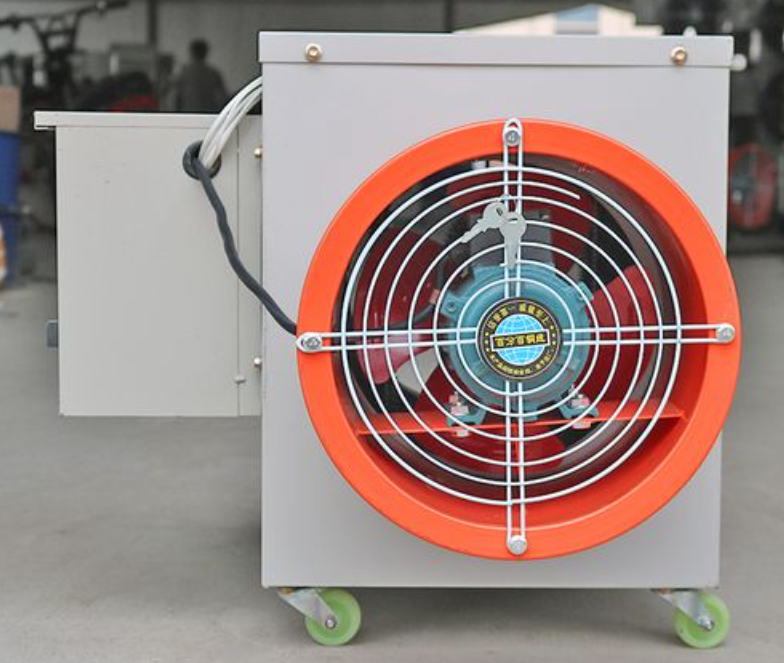

- Greenhouse Design: Proper design and installation of evaporative cooling systems are crucial for their effectiveness. Ensuring adequate coverage and distribution of cooling pads or systems within the greenhouse is essential.

- Management Practices: Regular maintenance, monitoring humidity levels, and adjusting system settings are integral to maintaining optimal conditions. Adequate water quality and system cleanliness are critical for system longevity and crop health.

Conclusión

In conclusion, the suitability of crops for cultivation using evaporative cooling techniques in greenhouses depends on their heat tolerance, water requirements, and adaptability to humidity variations. Understanding these factors aids in the selection of crops that benefit most from such cooling methods. Evaporative cooling systems offer a viable solution for optimizing growth conditions, but careful consideration of specific crop needs and environmental factors is pivotal for maximizing their benefits in greenhouse agriculture.

Productos relacionados