In the realm of industrial operations, the importance of proper ventilation cannot be overstated. Efficient airflow and temperature control are critical for maintaining a safe and productive work environment. Among the solutions available, FRP (Fiber-Reinforced Plastic) cone fans have gained recognition for their ability to enhance ventilation and cooling systems. However, when selecting an FRP cone fan supplier, careful consideration is needed to ensure that the chosen products meet industry standards and deliver reliable performance over time. This article delves into the key factors that should be considered when making this critical decision.

Introduction

Industrial environments often present challenges related to temperature regulation, air quality, and overall comfort for workers. Proper ventilation becomes a key element in addressing these challenges. FRP cone fans have emerged as a reliable solution due to their ability to efficiently circulate air, contributing to effective temperature control and improved working conditions. This article aims to guide decision-makers in choosing the right FRP cone fan supplier by highlighting essential factors that guarantee industry standards and dependable fan performance.

Understanding FRP Cone Fans

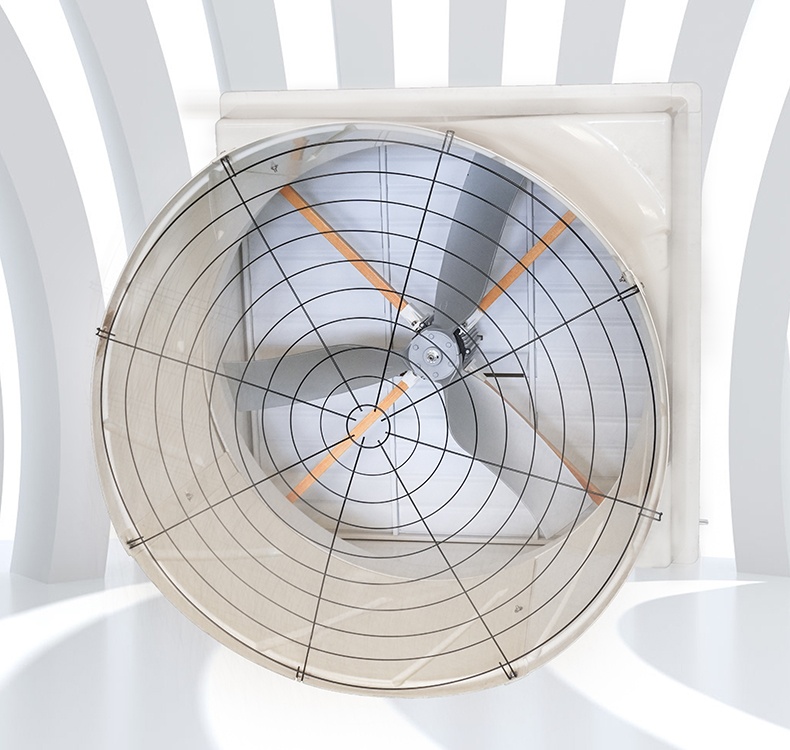

FRP cone fans are engineered to optimize airflow within industrial settings. Their design revolves around a cone-shaped structure that enhances the efficiency of air circulation. This design results in improved cooling and temperature regulation, making these fans suitable for a wide range of applications, from warehouses to manufacturing facilities.

Factors to Consider When Selecting an FRP Cone Fan Supplier

- FRP cone fan supplier’s Reputation and Experience

The reputation of a FRP cone fan supplier is a reflection of their track record in the industry. Established FRP cone fan suppliers with a solid reputation often possess a wealth of experience in designing and manufacturing FRP cone fans. Their experience indicates a deep understanding of fan performance and industry requirements, making them a more reliable choice.

- Compliance with Industry Standards

Industry standards serve as benchmarks for fan performance, safety, and quality. When selecting a FRP cone fan supplier, it’s essential to ensure that their products meet or exceed these standards. Adherence to standards guarantees that the fans are engineered to perform reliably and consistently, even in challenging environments.

- Material Quality and Corrosion Resistance

The longevity of FRP cone fans is directly influenced by the quality of materials used in their construction. FRP cone fan suppliers that prioritize high-quality FRP materials ensure that their fans are robust and resistant to wear and tear. Corrosion resistance is particularly crucial in environments where exposure to corrosive substances is prevalent.

- Design and Engineering Expertise

Expertise in fan design and engineering is a key factor that directly impacts fan performance. FRP cone fan suppliers with a deep understanding of fluid dynamics and aerodynamics can create fans with optimal airflow patterns. Expert design ensures that fans not only deliver efficient performance but also maintain their effectiveness over time.

- Testing and Quality Assurance

The importance of testing and quality assurance cannot be underestimated. Reputable suppliers subject their FRP cone fans to rigorous testing to ensure they meet specified performance metrics. Testing assures buyers that the fans they receive are of consistent quality and will deliver reliable performance.

Ensuring Reliable Performance Over Time

- Longevity and Durability

Fans constructed with high-quality materials and designed to meet industry standards are inherently more durable. Longevity directly translates into reduced maintenance and replacement costs. Investing in reliable fans ensures continued operation without frequent disruptions.

- Consistent Airflow and Cooling

Proper fan design ensures consistent and effective airflow, which directly influences temperature control. Consistent airflow contributes to the maintenance of a comfortable and productive work environment, minimizing temperature fluctuations.

- Energy Efficiency

Efficiently designed fans not only provide effective ventilation but also contribute to energy savings. Energy-efficient fans consume less electricity while maintaining optimal performance. Over time, these energy savings translate into lower operational costs.

- Minimal Maintenance Requirements

Fans constructed with high-quality materials and expert design require less maintenance. Reduced maintenance needs lead to decreased downtime and lower ongoing maintenance costs. Opting for low-maintenance fans contributes to overall operational efficiency.

Case Studies and References

Real-world examples provide tangible evidence of the impact of the factors discussed. Case studies showcasing successful partnerships between reliable FRP cone fan suppliers and industrial clients demonstrate how adherence to industry standards, material quality, and expert design lead to consistent fan performance over time.

Conclusion

Selecting an FRP cone fan supplier is a decision that significantly affects the efficiency and reliability of ventilation and cooling systems. By carefully evaluating factors such as the supplier’s reputation, compliance with industry standards, material quality, design expertise, and testing practices, industries can make informed decisions that ensure industry-standard products and reliable fan performance. A well-chosen supplier guarantees that FRP cone fans continue to deliver efficient airflow, contribute to temperature control, and create a conducive working environment, ultimately contributing to the long-term success of industrial operations.

Related Products